Our well-equipped precision machine shop allows fast response for virtually any type of precision CNC turning and milling.

Our history of excellent quality and value is driven by working closely with our customers and their engineering teams from design through production. Careful design review, casting simulation, and tooling production allow Kupral Spa to provide superior design and components at optimum value.

Components manufactured include:

bronze gear blanks for elevator/lift applications

bronze gear blanks for worm gear speed reducers

bushings

various bronze castings

various aluminium castings

Maximum casting weight that can be handled in our machine shop is 50 kg. Heavier parts can be machined by our supply chain partners.

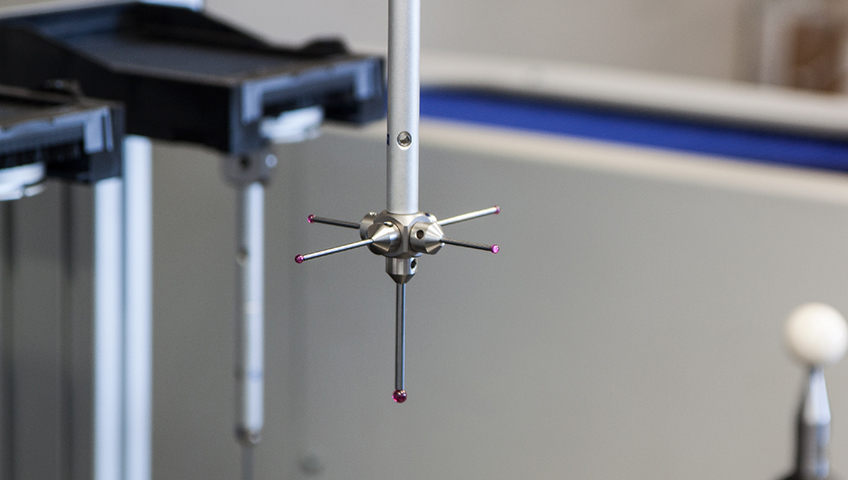

Our machine shop is equipped with twin spindle CNC lathes, single spindle CNC chucking lathes, CNC milling with automated pallet feeding, broaching, and a variety of other support equipment, all focused on meeting the most demanding technical requirements and on time delivery. For machining requirements beyond our capabilities, we partner with carefully selected partners with proven capabilities for quality, cost-effective, and on-time production.